Reinforcement of intersection - Vejlevej/Vestre Ringvej - Fredericia, Denmark

The intersection Vejlevej - Vestre Ringvej is one of Fredericia's most heavily trafficked intersections. The Vestre Ringvej itself is the access road to the harbour, as well as the industrial area in the north of the City.

On this page

- Topic

- Reinforcement of intersection

- Object

- Vejlevej/Vestre Ringvej

- City

- Fredericia

- State

- Fredericia Municipality

- Country

- Denmark

- Date

System

Project Description

Situation

The intersection had been rebuilt several times over the years and there had also been excavations in connection with the construction of district heating pipelines. The pavement had suffered from severe cracking and in several places there were also signs of bearing capacity problems.

Drill cores revealed that the asphalt pavement thickness varied from approximately 20-30 cm and in a few places even went down as low as 15 cm. The drill cores also showed that there were between 4 and 7 asphalt layers and several of the cores revealed poor or even no adhesion between layers.

Solution

Calculations made in MMOPP showed that the asphalt pavement intersection should consist of at least 18-20 cm of intact pavement based on a 20 year design period, speed of 30-50 km/h, base modulus of 40 MPa, an intact base (34-40 cm) and gravel subbase (16-20 cm). However, it was highly doubtful that these conditions were present. S&P also carried out an assessment using MMOPP with a pass-through rate of 20-30 km/h, and it revealed a pavement lifetime of 14 years. When further calculated with a reduced E-modulus of the asphalt wearing course of 1500 MPa (cracked base), the lifetime of the asphalt pavement would be as low as 12 years.

A rutting simulation was also conducted for the turning lanes where only the wearing course had to be replaced. The simulation showed that after only 10 years rutting in the pavement would most likely be more than 10 mm in depth.

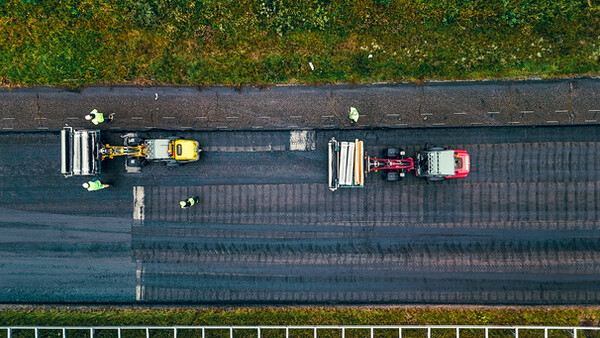

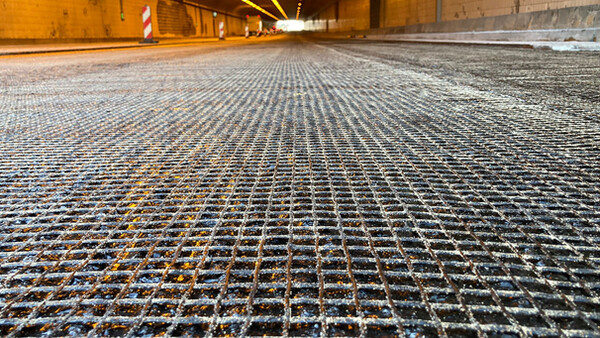

Based on the calculations, and in close collaboration with S&P, the client decided to mill to a depth of approximately 10 cm, then lay S&P Carbophalt® G 200/200 asphalt reinforcement on the intersection itself and subsequently overlay it with 6 cm ABB type 16 and 4 cm SMA 11. Additionally the turning lanes leading up to the intersection were reinforced with S&P Carbophalt® G to reduce the risk of rutting and overlaid with 4 cm SMA 11.

Once the project had started and the asphalt was milled, it was found that the subbase was in fact significantly thinner and worse than expected. As a result of this, the worst areas therefore had to be replaced.

The solution with S&P Carbophalt® G 200/200 is expected to increase the service life to at least 20 years, which is a significant improvement on the previous assessments.

Project tracking

A visit to the project location in 2022 revealed that the intersection remained in top condition - as expected. Over the coming years, S&P will actively continue to track the project to ensure that the wearing course remains in good condition during the intended lifetime of the road.

Material

S&P Carbophalt® G 200/200

S&P Carbophalt® G