Asphalt pavement repair - State roads L281 and L333 - Märkisch-Oderland, Germany

On January 1st 2016, the Brandenburg State Roads Authority reclassified the state roads, L281 Neureetz - Altranft and L333 Golzow - Genschmar, as district roads. In the reclassification procedure, the relinquishing authority agrees with the future owner of the road on who will have to pay for any upcoming investments. In this case, the district of Märkisch-Oderland received financial compensation. The district administration was therefore responsible for planning the investment in the urgently needed rehabilitation of the infrastructure.

On this page

- Topic

- Asphalt pavement repair

- Object

- State roads L281 and L333

- City

- Märkisch-Oderland

- State

- Brandenburg

- Country

- Germany

- Date

System

Project Description

Situation

Due to its advanced age and inadequate maintenance measures in the past, the road body showed extensive damage in the form of deep cracks and superficial deformations. An additional challenge for the rehabilitation resulted from the fact that parts of the roads run through urban areas and on old concrete pavements.

The district of Märkisch-Oderland commissioned the Technical Office for Water Management and Regional Culture (Technische Büro für Wasserwirtschaft und Landeskultur GmbH) from Bad Freienwalde with the technical planning and construction supervision of the project. The evaluation of the soil characteristics, the existing structure and the damage mechanisms revealed a residual substance value in many stretches, which would have required a full reconstruction of the roads with regard to conventional rehabilitation methods. As this would not have been possible with the available funds, an economic alternative was sought.

Solution

The concept

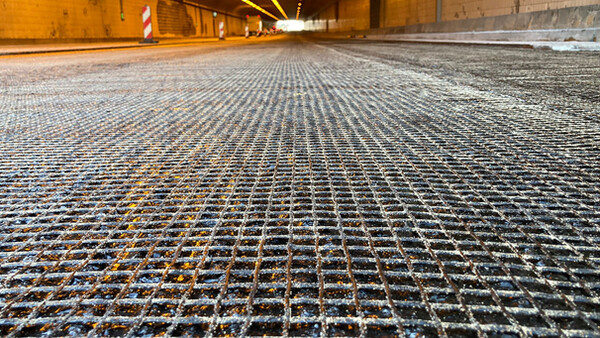

As a result of the financial constraints, a detailed rehabilitation concepts for the two roads were developed in co-operation with the engineers at S&P Germany. The general scope of the concept was to preserve the existing road body and to renew the heavily aged and cracked surface course with the aid of an asphalt reinforcement interlayer. The task of the asphalt reinforcement in this context is to prevent the reflection of cracks and joints from the existing pavement into the new asphalt layers and thus prevent subsequent damage mechanisms such as water ingress and frost cracking.

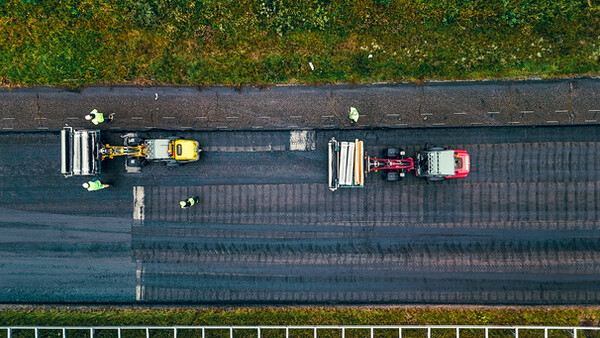

In order to ensure an economical repair and the smoothest possible construction process, the jointly developed renovation variants were adapted to the existing framework conditions:

- In areas with height constraints, a replacement of the 3.5 cm thick asphalt wearing course was specified in accordance with the ZTV BEA-StB. The asphalt reinforcement was laid on the milled surface.

- Outside of urban areas, rehabilitation was planned using the overlay paving method in order to utilise the existing residual substance as effectively as possible. Here, the asphalt reinforcement was installed on top of the existing pavement and overlaid with a 3.5 cm thick wearing course.

- In areas with concrete pavement, the application of a 6 cm thick levelling course on top of the existing pavement was specified. During the subsequent overlay with the asphalt reinforcement and wearing course, the best possible anchoring and thus effectiveness of the reinforcement between the asphalt layers can be achieved.

Excellent support and co-operation during installation

Apart from their effectiveness, the handling of asphalt reinforcement systems in site practice is the decisive factor for achieving a long-term rehabilitation result. In addition to the considerable size of the construction site, the high summer temperatures of over 30 °C that prevailed during the work in June 2019 presented a particular challenge. At high surface temperatures, there is a risk that the adhesive effect of the bitumen emulsion is reactivated, which can make it difficult for pavers and trucks to drive over the laid reinforcement. Thanks to the excellent co-operation and close co-ordination between the road construction company RASK GmbH and the certified S&P specialist installer, the planned construction schedule could be implemented without any delays. The factory-applied sanding of the S&P asphalt reinforcement as well as the high positional stability of the expertly laid product enabled problem-free feeding of the paver over the laid reinforcement. The key project participants Mr. Bozionek (site manager RASK GmbH), Mr. Skor (TBWL GmbH) and Mr. Hundertmark (District Märkisch-Oderland) were highly satisfied with the result and the excellent cooperation between the companies involved.

Project tracking

By focusing the technical planning on optimal use of the existing substance and the use of an high performance product, it was possible to use the available budget economically and avoid a costly and time-consuming full reconstruction of the two district roads. Thanks to the close co-ordination and good co-operation of those involved, the project was completed on schedule and handed over in impeccable quality despite the demanding framework conditions. This is also underlined by the layer bond values determined in the course of a control test by the certified RAP-Stra test agency ASPHALTA. The required layer bond according to Leutner of 15 kN, in accordance with ZTV Asphalt-StB, was achieved without any problems with S&P Glasphalt® G, both in the overlay paving sections as well as on milled surfaces.

80 % saving on CO2 emissions thanks to S&P solution

Based on figures from the Swedish National Road Administration (Trafikverket), the use of S&P asphalt reinforcements in this project resulted in a saving of approximately 1,700 t CO2eqv - or 79.68 % - compared to replacing the entire bonded superstructure.

This figure alone underlines the opportunities that the use of modern asphalt reinforcement systems from S&P offer for a sustainable transformation of road construction.

Material

80 000 m² - S&P Glasphalt® G