Neubiberg Tunnel

The Neubiberg Tunnel is a 327 metre long tunnel on the federal Highway A8 (Munich-Salzburg) in the municipality of Neubiberg in the district of Munich. It runs under the former Neubiberg airbase runway in what is now the Hachinger Tal landscape park. The tunnel was equipped with a concrete pavement during construction.

On this page

- Topic

- Carbon reinforcement on concrete slabs

- Object

- Neubiberg Tunnel, Highway A8

- City

- Munich

- State

- Bavaria

- Country

- Germany

- Date

- Duration

- 1 Week

System

Project Description

Situation

In order to improve driving comfort, an asphalt wearing course was applied to the existing concrete slabs many years ago. However, due to the low tunnel height, only a thin asphalt layer could be used, as otherwise there was a risk of problems with the clearance height of the vehicles.

Due to its low layer thickness and the high traffic load, the asphalt wearing course was subjected to accelerated damage, particularly in the form of rutting and cracking. On average, a complete replacement was therefore necessary every year. In the ramp areas of the tunnel structure, intensive braking also led to increased shear stresses, which further accelerated the development of damage.

Solution

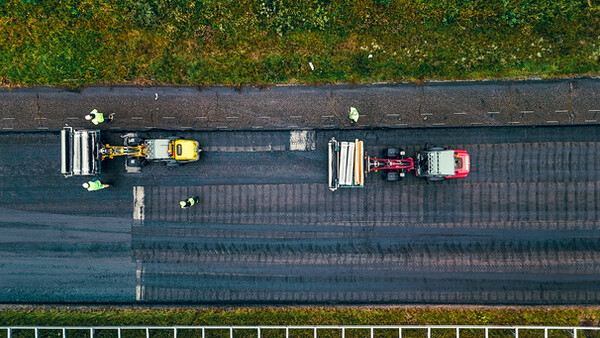

To protect the asphalt surface layer from deformation and future damage, the federal motorway administration (Autobahn GmbH) decided to install a carbon reinforcement on the concrete slabs. The asphalt reinforcement helps to distribute traffic loads evenly and absorb the stresses from the underlying concrete slabs - thus effectively preventing the formation of cracks in the wearing course.

The repair work was divided into two areas:

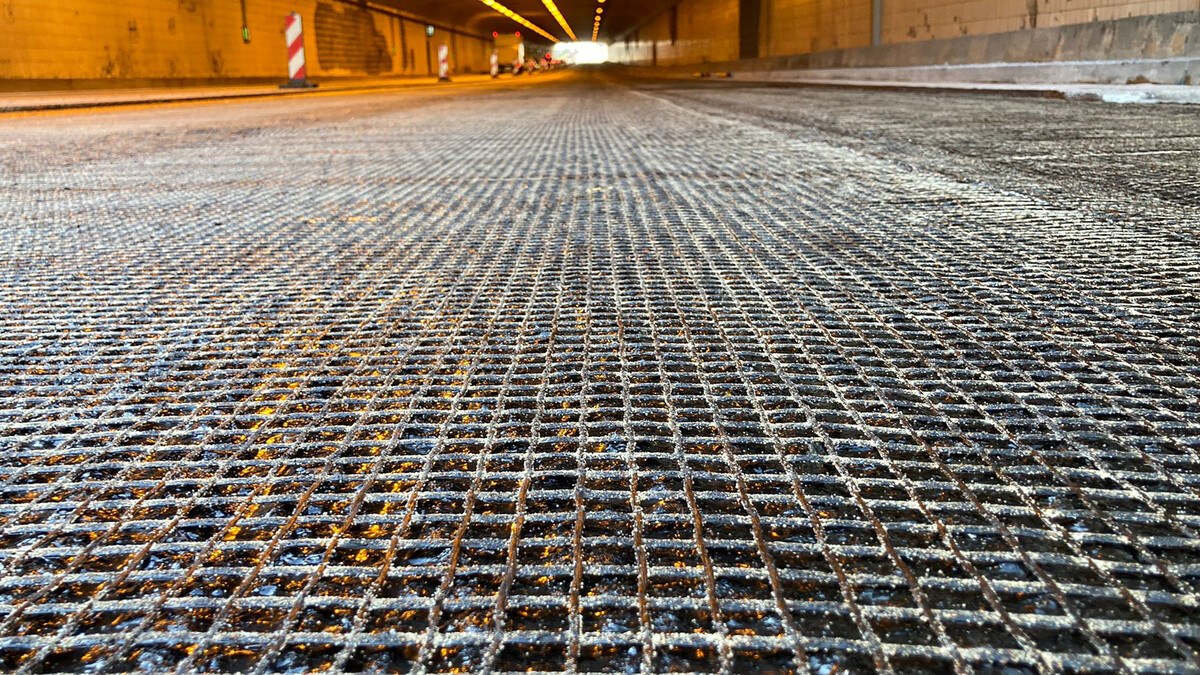

Ramp areas: Installation of S&P Carbophalt® G underneath a 3.5 cm thick wearing course of SMA 8 S on top of an existing asphalt binder course.

Tunnel area: Installation of S&P Carbophalt® G 200 below a 3.5 cm thick SMA 8 S layer directly on the existing concrete slabs.

To ensure trouble-free overlay in summer temperatures, the asphalt reinforcement was treated with a lime hydrate suspension (Asphacal® TC) after installation. This product prevents the emulsion used for layer bonding from depletion and the reinforcement from sticking to the tyres and tracks of the paving machines. The construction process went smoothly.

Project tracking

Since the measure was implemented, the service life of the tunnel wearing course has to date been demonstrably increased by a factor of 2.5. We worked closely with our experienced partner Nadler Straßentechnik GmbH and Autobahn GmbH to plan this challenging project. The work was carried out by our long-standing specialist installation partner SSVG, which reliably and precisely implemented both the application of the asphalt reinforcement and the application of the lime hydrate suspension. Strong teamwork for a convincing result.

CO2 Savings

Until S&P asphalt reinforcement grids were installed, this section of road required repaving on a yearly basis. By utilising this data it has been possible to make a CO2-saving calculation based on Global Warming Potential (GWP) figures from the OEKOBAUDAT national database. During the observed 3 year period the solution implemented using S&P asphalt reinforcement grids has led to a reduction in CO₂-equivalent emissions - from material usage alone - of around 44%. As this calculation considers only the materials used, actual CO₂ savings would be even greater when including other factors such as milling, transportation and general jobsite operations tied to repeated repairs. Should the road continue to remain damage free and in no need of rehabilitation, this CO₂-equivalent emissions savings will continue to increase yearly, based on the previous yearly rehabilitation cycle of the road section.

Material

S&P Carbophalt® G 6000 m², S&P Carbophalt® G 200/200 6300 m²