Reinforcement of the Viaducs du Chêne

The Viaducs du Chêne are part of the important A1 motorway from east to west. The bridges from the 1970s no longer met the more stringent structural requirements of today. Thanks to special adhesive reinforcements from S&P, a lot of material and effort could be saved during the repair.

On this page

- Topic

- Reinforcement of the Viaducs du Chêne

- Object

- Viaducs du Chêne

- Location

- Autobahn N01

- City

- Essert-Pittet / Chavornay

- State

- Vaud

- Country

- Switzerland

- Date

System

Project Description

Situation

The Chêne viaducts are two parallel steel-concrete composite bridges with two girders. They date from 1977-1978 and have a total length of over 365 metres each. Each bridge consists of twelve segments with a typical span of 32.75 metres.

These viaducts are part of the N01 motorway linking Lausanne with Bern. Today, the A1 motorway, which is over 400 km long, is an important east-west axis linking the French border with the Austrian border. The longest motorway in Switzerland crosses the road to Yverdon and a railway line on the viaducts. These structures are of great importance on this busy section of motorway.

Problem

The steel used at the time no longer met today's requirements. As a result, the safety of the structure was no longer guaranteed for lorries weighing more than 20 tonnes on carriageway 2 and the emergency lane in both directions. In addition, special transport vehicles could no longer drive on the two bridges. The Federal Roads Office (FEDRO) then decided to carry out work in 2022-2024 to reinforce the abutments, main girders, carriageway slab and supports of the bridges.

Solution

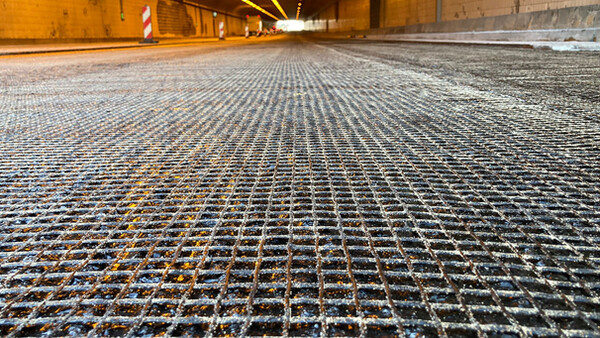

The planned solution was to reinforce the concrete carriageway slab of the bridge in the area of the supports. As the forces to be absorbed were considerable and the quality of the concrete permitted this, two to three layers of CFRP laminates would have had to be arranged on top of each other.

However, gluing laminates on top of each other leads to a higher material requirement, a considerable increase in installation time and a high consumption of epoxy resin. In addition, applying one laminate on top of another is a laborious process that requires a high degree of precision. In co-operation with our engineering consultants and application technicians, we therefore began to develop an alternative with special adhesive reinforcements.

Thanks to our own production facilities, we were able to customise our carbon laminates with a thickness of 2.8 mm for this construction site. This solution enabled the construction company Bernasconi & Cie SA to save time during installation, reduce the amount of resin required and thus increase the efficiency of the reinforcement works. Thanks to the customised S&P C-Laminate, a total of more than 3,000 m of CFRP plates, over 4,000 kg of epoxy resin and a lot of working time for sanding and application were saved.

Following this work, FEDRO reopened the viaducts for special transport vehicles and lorries weighing over 20 tonnes can now drive on the second lane in both directions.