Asphalt pavement repair - DK3 State road through Pyrzyce - Pyrzyce, Poland

S&P worked together with the road administrator to come up with a long term durable solution for the DK3 State road in the Polish City of Pyrzyce, that following it's success, would ultimately be utilised on further road sections within West Pomerania.

On this page

- Topic

- Asphalt pavement repair

- Object

- DK3 State road through Pyrzyce

- City

- Pyrzyce

- State

- West Pomerania

- Country

- Poland

- Date

System

Project Description

Situation

The existing pavement structure consisted of a gravel subbase, with asphalt layers on top. The total thickness of the asphalt layers were 11-14 cm and deflection measurements carried out in 2004 revealed that the load capacity of the surface corresponded to the capacity of the gravel subbase, meaning that there were serious issues with the structural integrity of the road.

The renovation plan from the road administrator was to mill to a depth of 21-23 cm and lay new layers with a total thickness of 27 cm. However, due to the fact that in some places the thickness of the road structure was lower than 23 cm, and in order to not interfere with the existing substructure, the road administrator decided to rely on the advice from S&P and changed the renovation plans.

Solution

The solution that was implemented was to lay 2 layers of S&P asphalt reinforcement grids to to make optimum use of the existing structural substance on the one hand, and on the other hand to ensure that the new structure is able to withstand the future traffic loads. This was done as follows:

- Milling was carried out to a depth of 2-3 cm

- A 3 cm levelling layer was laid

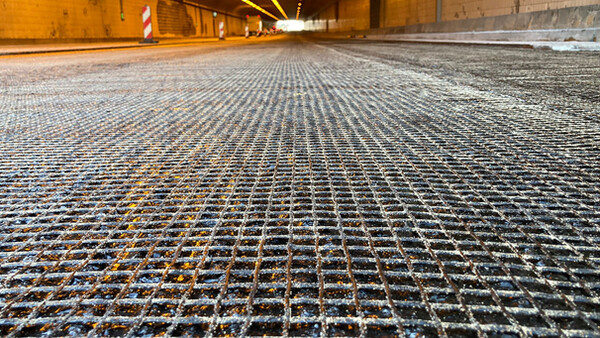

- Pre-bituminised S&P Carbophalt® G was installed onto bitumen tack coat

- A 6 cm BA 0/16 binder course was installed on top

- Pre-bituminised S&P Glasphalt® G was installed onto bitumen tack coat

- Finally a 4 cm SMA wearing course was laid on top

The combination of the two S&P asphalt reinforcement products in this project had specific goals. The high tensile carbon fibre in S&P Carbophalt® G placed on the underside of the new asphalt structure is designed to increase flexural strength and stiffness, allowing for more uniform load transfer across the entire structure. S&P Glasphalt® G under the asphalt wearing course acts as an additional safeguard against the possible propagation of cracks from the substructure and stress cracks from the traffic load.

The total thickness of the newly laid asphalt layers equalled approximately 13 cm, which was a huge saving on the previous plan where new layers totalling 27 cm were due to be laid. This ultimately led to a substantial saving on resources, construction and road closure times, as well as being able to keep the original pavement structure in place.

Project Tracking

In Spring 2007 new control measurements were taken revealling a significant decrease in deflections compared to the initial condition. The success of the project led to the decision to implement this recommendation as a standard solution in the following years. In 2007, approximately 8000 m² of road section on the DK 6 in Malechowo was relaid using this technology. Then the same solution was also used in 2009 in Ryman and Nieradz, where 11000 m² and 22000 m² of road surface were rebuilt in the same way.

Also, following the installation of the S&P asphalt reinforcement grids, S&P continued to track the project to ensure the road remained in very good condition. This can be seen in the images below from 2011 and even 8 years after the installation in 2014, where no damage was observed on the wearing course.

CO2 Emission Savings

Knowing that the previously proposed solution would have required a new 27 cm superstructure enabled a calculation using Global Warming Potential figures from various national databases to evaluate the impact of S&P’s solution on CO₂ emissions reduction. The results show that the double-layered S&P asphalt reinforcement grid solution achieved approximately 40% CO₂-equivalent emission reductions in material usage alone for this project. These figures account only for material savings; the actual CO₂ reductions would be significantly higher when considering additional factors, such as the increased milling, transport and other jobsite operations associated with the much thicker initial superstructure proposal.

Material

S&P Carbophalt® G

S&P Glasphalt® G

The S&P asphalt reinforcements consist of carbon and/or glass fibre strands that are 100% impregnated with bitumen. The flexible, adaptable grid allows laying in curves as well as adaptation of the meshes to the subgrade or its surface structure. The granular aggregate of the new asphalt layers can penetrate the grid meshes, and a very high layer bond can be achieved via this interlocked connection. This ensures that the fibres are optimally bonded and can effectively absorb crack-generating tensile forces. This effectively prevents the reflection of cracks from the existing pavement into new asphalt layers and the resulting consequential damage. The reinforcement also increases the overall stiffness of the system and thus prevents future stress cracks.