Gothenburg Airport test area

At Landvetter Airport in Gothenburg, Sweden, two different superstructures were tested with S&P carbon fibre asphalt reinforcement. The results show that the load-bearing capacity of flight operation areas can be significantly increased in this way. One of the two test set-ups even enables massive material savings.

On this page

- Topic

- Gothenburg Airport test area

- Object

- International Airport

- City

- Gothenburg

- Country

- Sweden

- Date

System

Project Description

Situation

The Pavement Classification Number (PCN) is of crucial importance for aircraft movement areas. The PCN indicates the load-bearing capacity of runways, landing strips and taxiways. This is compared with the Aircraft Classification Number (ACN), which represents the load carried by the aircraft.

If the ACN is greater than the PCN, the aircraft operating area is overloaded and there is a risk of the structure being destroyed, which can result in costly refurbishment. The International Civil Aviation Organisation (ICAO) therefore introduced the ACN-PCN method in 1981 to compare the load from flight operations with the load-bearing capacity of all flight operation areas.

Solution

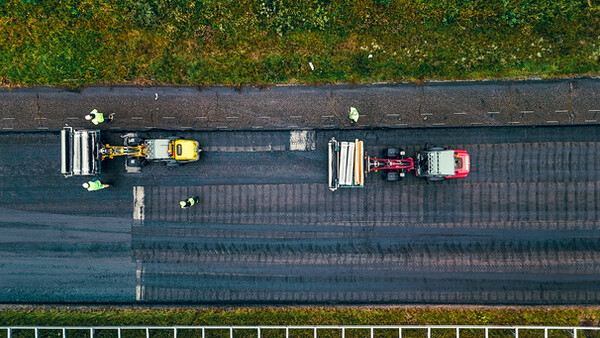

In July 2016, a test area was created at Landvetter Airport in Gothenburg, Sweden, to analyse and assess reinforced asphalt. The SWECO Group supported the project. The purpose of the test area was to investigate the influence of asphalt inlays consisting of high-strength fibres on the PCN. The surface was reinforced with S&P Carbophalt® G 200/200 and the experts carried out the measurements using a Falling Weight Deflectometer (FWD). The aim was to increase the PCN to PCN 70 F/A/W/T for 100,000 annual load transitions; the previous PCN was less than 60 in some of the test fields.

Two different superstructures were analysed based on calculations: Part of the test area was reinforced with two layers of S&P Carbophalt® G 200/200, 50 mm and 150 mm below the surface. The total asphalt thickness was 324 mm. A further section was reinforced with a layer of asphalt reinforcement at 50 mm below the surface, for a total asphalt thickness of 441 mm. For both structures, the FWD measurements showed the same results, namely that the PCN 70 F/A/W/T can be achieved with 100,000 annual load transitions.

Reduced overall structure with two layers

The great advantage of the two-layer structure is the reduced overall structure. Due to many circumstances, such as existing installations, lights, etc. on flight operation areas, it is not possible to build upwards in most cases. This means that when the asphalt structure is enlarged, it must be ‘built down’, i.e. the gravel base layer must be reduced and removed and a thicker asphalt package rebuilt on top.

For an area of only 1000 m², this means a saving of approx. 270 tonnes of asphalt and approx. 199 tonnes of gravel movement in this case. The enormous savings potential becomes even clearer when you consider that the areas to be resurfaced at airports usually cover several tens of thousands or hundreds of thousands of square metres.

Fewer cracks and deformations

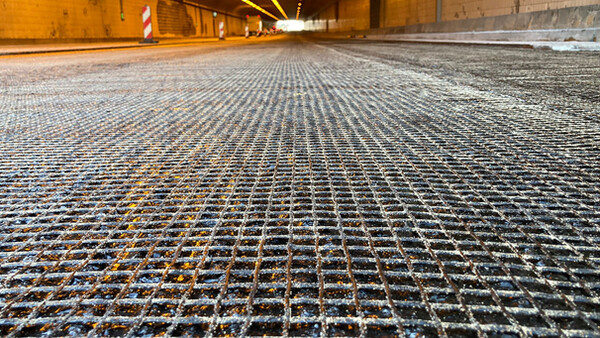

Further advantages of the two-layer reinforcement are the prevention of crack reflection in the asphalt layers above the lower layer of reinforcement by acting as tensile reinforcement, similar to steel in concrete, as well as the reduction of deformations in the asphalt due to the upper layer of reinforcement.

Deformations such as rutting primarily occur at higher temperatures in the asphalt or thermal stress, which also occurs due to friction, for example. Further calculations and measurements on the test surfaces show the influence of S&P Carbophalt® G 200/200 on the stiffness of the asphalt: The higher the temperature in the asphalt, the lower the modulus of elasticity and the greater the influence of the reinforcement on the modulus of elasticity of the asphalt (see graph).

S&P Carbophalt® G 200/200 therefore not only reduces the formation of cracks from crack reflection in new asphalt layers and rutting, but also increases the load-bearing capacity of airfields.