Recycling of asphalt reinforcement - State road - Mauth-Kreuzberg, Germany

The recycling of reinforced asphalt is often seen as problematic for various reasons. Detailed documented investigations from practical road construction in Germany show that most reservations are unfounded. The tests also revealed exciting new findings that need to be researched in the future.

On this page

- Topic

- Asphalt reinforcement recycling

- Object

- State Road

- City

- Mauth-Kreuzberg

- State

- Bavaria

- Country

- Germany

- Date

System

Project Description

Situation

In the past, there have been bad experiences on the market with milling and recycling reinforced asphalt pavements. S&P therefore carried out pioneering work back in 2015 and was one of the first manufacturers of asphalt reinforcements to carry out a large-scale practical trial. Even then, it became clear that the recyclability of such pavements depends heavily on the reinforcement used.

Broad-based practical test

At the suggestion of a large state building authority in Germany, S&P has now been given the opportunity to verify these findings with a further practical test. In summer 2019, the company carried out the test in cooperation with well-known partners from the road construction sector.

Solution

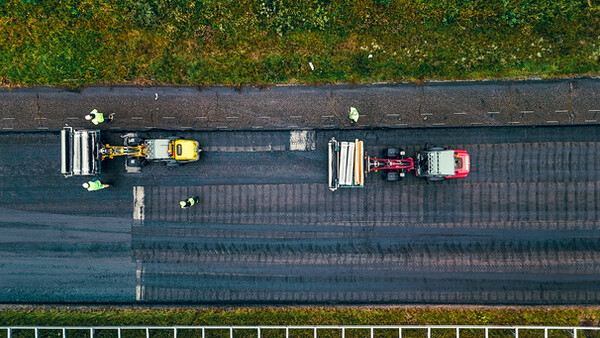

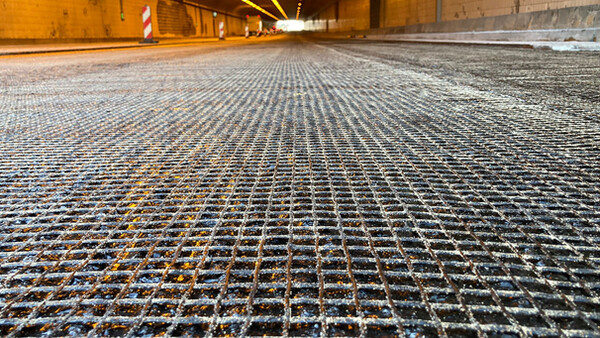

For the test, a 50 x 2.30 metre test area was constructed on the Bavarian state road 2127 Mauth-Kreuzberg under conditions that were as close to reality as possible. Within two days, the participants milled off the old surface course, laid the S&P Glasphalt® G asphalt reinforcement in accordance with the specifications and laid the new surface course. On the third day, experts took two drill cores to analyse them in two independent laboratories for their layer bond.

Milling like normal pavement

The actual milling test took place on the fourth day. The machine was able to remove the material in one pass without any problems and the machine operator did not notice any difference to the non-reinforced surface. Afterwards, it became apparent that the milling drum had completely cut and picked up the reinforcement. No adhesions or fibre residues were visible on the drum.

No abnormalities in the laboratory

The independent experts were also unable to observe any difficulties during the first laboratory analysis due to the fibre residues present. Even when a higher proportion of reinforcement residue was added during the second extraction, no negative effects were observed during the analysis.

Preparation with pre-screening

This meant that nothing stood in the way of processing the milled material in the asphalt plant. After screening and crushing, the granulate had a homogeneous appearance, with some fibre residues visible. The only thing that became apparent was that some fibre residues could be deposited in the plant.

Glass fibres in the mixing plant inconspicuous

The final phase of the project in August 2020 involved producing a surface course mix at the asphalt mixing plant and paving it afterwards. The mix was supplemented with 25% recycled granulate interspersed with glass fibre residue from the test field of the 2127 Mauth-Kreuzberg state road. The mixing foreman was unable to detect any influence of the fibre residues on production.

Paving with standard road construction machinery

The road construction company then processed the mix as part of the repair work on the B12 Passau - Philippsreuth motorway at the Wasserscheide car park. The mix was laid on around 400 square metres in very good weather conditions using standard road construction machinery. The foreman and site manager noted that the fibre components had no impact on the construction work.

Adhering to established processes

The results from this test under real conditions once again show that durable asphalt pavements reinforced with S&P glass fibres are not fundamentally at odds with recyclability. Laboratories, recycling companies, asphalt mixing plants and road builders can retain their tried and tested processes and use their standard machinery and equipment.

However, the tests have brought new details to light, which S&P and the project partners will analyse in greater depth in the next steps. These include various questions relating to identification, classification, laboratory analyses and quality assurance. The aim is to provide all those involved in the recycling process with guidelines on how to handle asphalt reinforcements made of glass and carbon fibres.