Asphalt pavement repair - Ayrton Senna Highway, SP-070 - São Paulo, Brazil

The SP-070 is an important transport link between São Paulo and Campos do Jordão, Vale do Paraíba and Rio de Janeiro, as well as being the main access route to Guarulhos International Airport.

On this page

- Topic

- Asphalt pavement repair

- Object

- Ayrton Senna Highway, SP-070

- City

- São Paulo

- State

- São Paulo State

- Country

- Brazil

- Date

- Duration

- 4 Years

System

S&P Case Study

- Download PDF (2.8 MB)

Project Description

Situation

Due to excessive cracking of the asphalt wearing course, lanes of the highway had to be resurfaced approximately every 6 months at recurring high costs. This also meant repeated traffic disruptions as well as a waste of resources.

The severe damage pattern was caused by reflection cracking from a 25 cm thick cement-bound base course, which was completely cracked due to the unstable subsoil and high daily traffic volumes (90,000 vehicles per direction, of which approx. 15 % are heavy goods vehicles).

This project had been used as a test section under extreme conditions (unstable base) and usually such projects are typically problematic when using asphalt reinforcement products. In fact interest in this particular project was so high that the University of São Paolo were involved in the tracking of the project and supported by carrying out jobsite tests, as well as analysis.

Solution

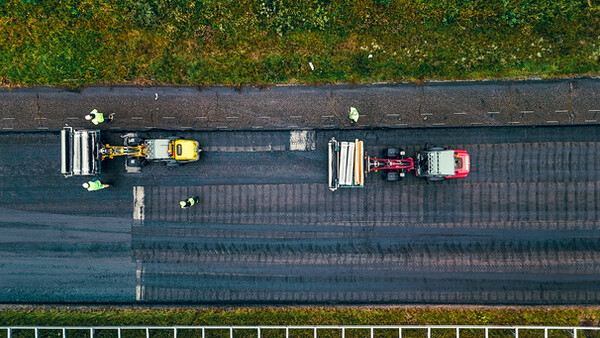

On 18th/19th April 2011, S&P asphalt reinforcement grids were installed on various sections on lane 4 of the highway. Since the various sections had differing levels of stability and damage, the grid and wearing course combinations were recommended by S&P based on the severity of the damage pattern. These sections can be seen below:

- km 17+500 to 17+600 Glasphalt G + 5cm CBUQ (bitumen concrete wearing course)

- km 17+600 to 17+700 Carbophalt G + 5cm CBUQ

- km 17+700 to 17+850 Carbophalt G + 8cm CBUQ

- km 17+850 to 17+950 Carbophalt G + 5cm CBUQ

- km 17+950 to 18+050 Glasphalt G + 5cm CBUQ

The goal was to achieve a significant extension of the maintenance intervals by at least doubling the previous 6 month life span of the wearing course through the use of S&P asphalt reinforcements.

Project tracking

In order to get a direct comparison of the effect that the S&P asphalt reinforcement grids had on the road structure, a month later in May 2011 lane 3 was re-surfaced - but this time without any asphalt reinforcement grid in the structure. Subsequently there were further reviews of the highway during the following months and years with the following conclusions:

| Date | Time elapsed | Condition of lane 4 (with grid) | Condition of lane 3 (without grid) |

|---|---|---|---|

| February 9th 2012 | 10 months | Very good condition | Already showing signs of degradation and punctual repairs were already carried out |

| September 17th 2012 | 17 months | Very good condition | Completely repaved for a second time, as the lane was deemed no longer safe |

| May 23rd 2013 | 25 months | Good condition | Completely cracked and already in need of repaving again |

| June 5th 2014 | 37 months | Light cracks appeared, but not enough for the lane to be deemed unsafe and it passed the external inspection from ARTESP | Completely repaved for a third time following the excessive cracking it had suffered |

| January 28th 2015 | 45 months | No further degradation was observed and at least another year of service life was expected |

CO2 Emission Savings

The direct comparison between lanes 3 and 4 enabled a calculation using Global Warming Potential figures from various national databases to demonstrate the impact of S&P’s solution on CO₂ emissions reduction. Lane 4, reinforced with S&P materials, proved significantly more sustainable than the unreinforced lane 3. Over the observed 45-month period, CO₂-equivalent emission reductions were at least 50 % based on material usage alone on this project. These figures focus solely on material savings; actual CO₂ reductions would be considerably higher when including additional factors such as milling, transport, and other jobsite operations required for repeated repair cycles.

Summary

In summary the S&P reinforced lane 4 had shown a lifetime of more than 3 times longer than the lane 3 that was repaired at the same time. This despite the fact that lane 4 was the inside lane of the highway and therefore our assumption is that it would have received the higher and heavier traffic loads. Not only that but the lane with S&P asphalt reinforcement grids also far exceeded the project goal of having a lifespan of 12 months.

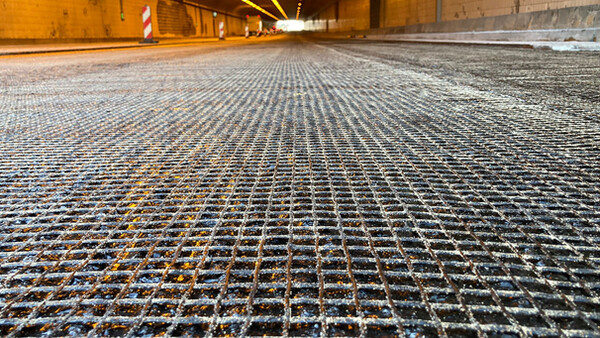

The S&P asphalt reinforcement grids are pre-impregnated with bitumen, and this together with the open grid structure leads to excellent bonding of the grid within the layers. This bonding is critical when considering how the grids work by absorbing and distributing crack inducing forces, which in turn protects the new wearing course by delaying the propogation of cracks to the surface.

In this case S&P worked together with the client to provide a sustainable solution despite the challenges with the very unstable subbase and high traffic loads. Further information can be found in the images below.

In August 2015, the road profile had to be completely changed to incorporate new exits for the airport. Therefore, it has not been possible to continue the project tracking further as the road structure was completely renovated - including replacing the unstable subbase.