S&P Product - Trail

JOSN

Product Information

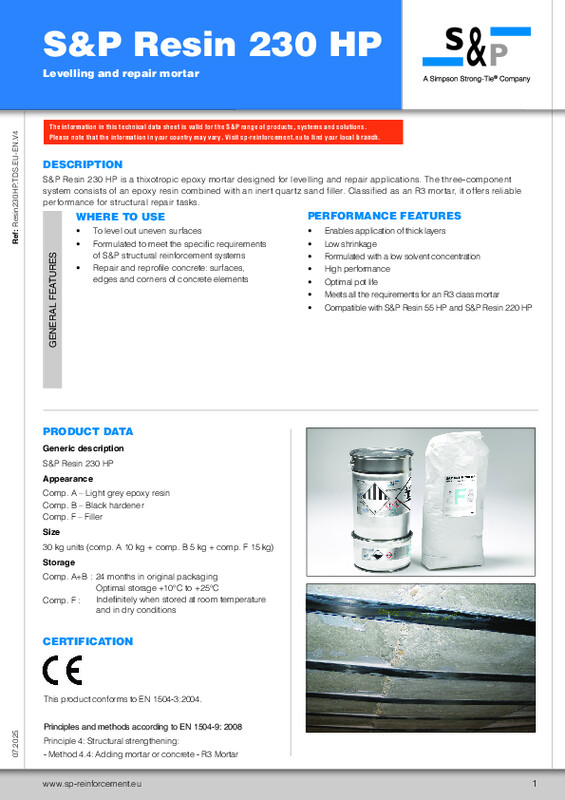

S&P Resin 230 HP is a thixotropic epoxy mortar designed for levelling and repair applications. The three-component system consists of an epoxy resin combined with an inert quartz sand filler. Classified as an R3 mortar, it offers reliable performance for structural repair tasks.

Features and Applications

Feature

- Enables application of thick layers

- Low shrinkage

- Formulated with a low solvent concentration

- High performance

- Optimal pot life

- Meets all the requirements for an R3 class mortar

- Compatible with S&P Resin 55 HP and S&P Resin 220 HP

Applications

- To level out uneven surfaces

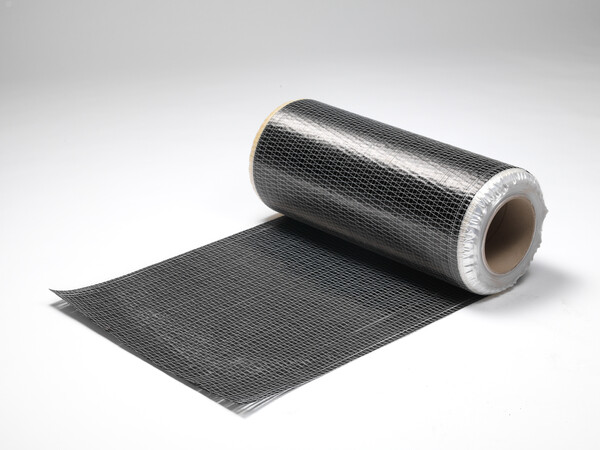

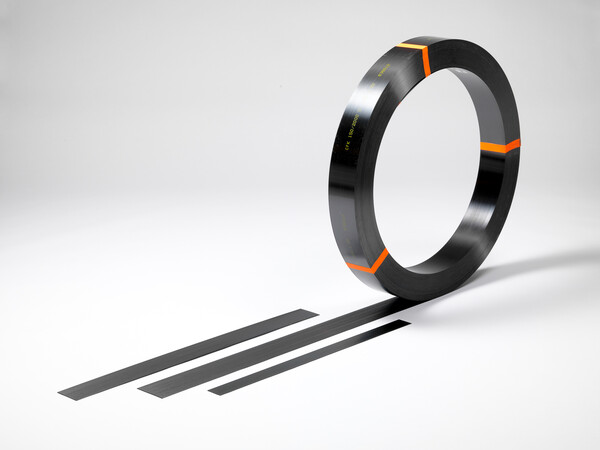

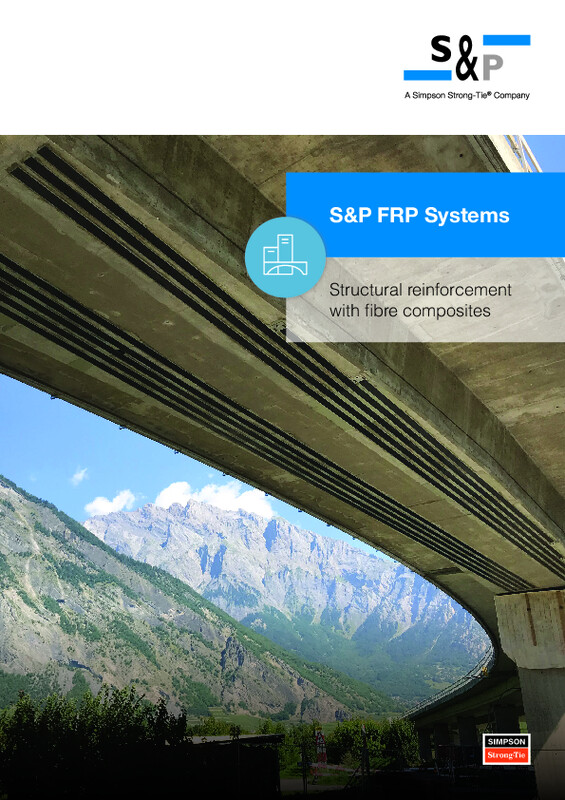

- Formulated to meet the specific requirements of S&P structural reinforcement systems

- Repair and reprofile concrete: surfaces, edges and corners of concrete elements