S&P Product - Trail

S&P Resicem HP

Structural epoxy adhesive, laminating resin and bonding agent

JOSN

Product Information

S&P Resicem HP is a structural adhesive for different materials like concrete, carbon fibre, glass fibre, aramid and steel. It is a high performance, 3-component epoxy resin. In comparison to conventional epoxy resins, S&P Resicem HP improves vapour exchanges between the substrate and the external environment.

Features and Applications

Feature

- Suitable for dry and damp concrete surface (max. residual moisture 12%)

- Good wettability and stability

- High performance

- Easy to mix and apply

- Can be applied by machine

- Very good adhesion to most construction materials

- Formulated without solvent

- No primer needed

- Low shrinkage

Applications

- S&P Resicem HP is used as a laminating resin for the following S&P sheet systems:

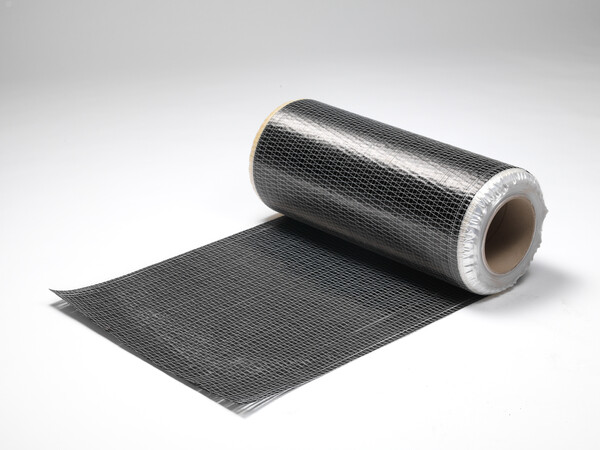

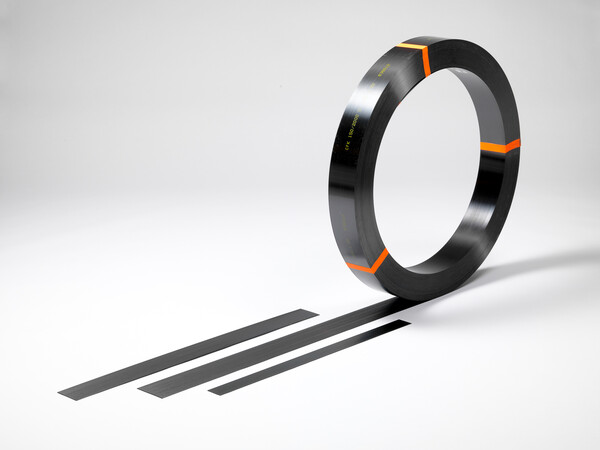

– S&P C-Sheet

– S&P G-Sheet - Bonding agent for concrete elements, including

– Bonding agent between fresh and hardened concrete

– Bonding precast concrete elements

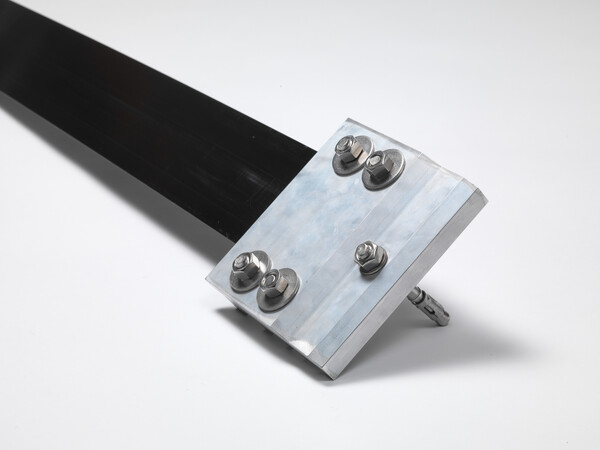

– Bonding steel to concrete