S&P Product - Trail

JOSN

Product Information

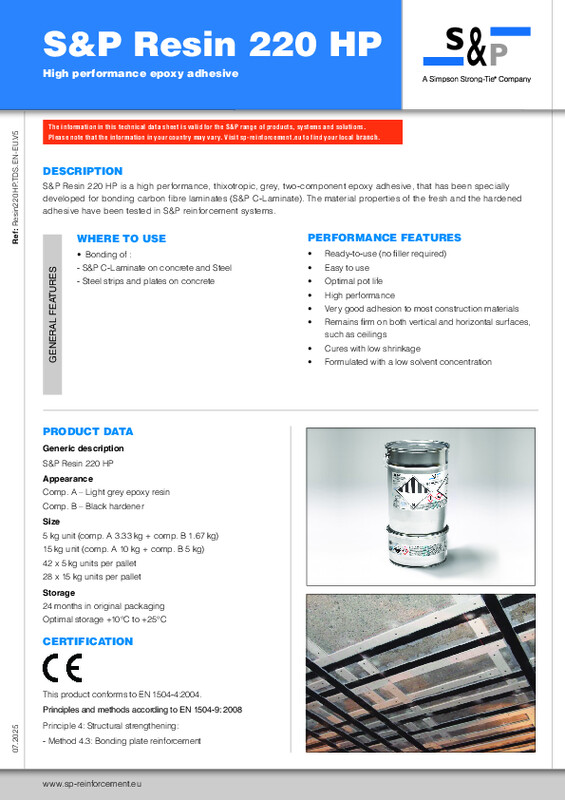

S&P Resin 220 HP is a high performance, thixotropic, grey, two-component epoxy adhesive, that has been specially developed for bonding carbon fibre laminates (S&P C-Laminate). The material properties of the fresh and the hardened adhesive have been tested in S&P reinforcement systems.

Features and Applications

Feature

- Ready-to-use (no filler required)

- Easy to use

- Optimal pot life

- High performance

- Very good adhesion to most construction materials

- Remains firm on both vertical and horizontal surfaces, such as ceilings

- Cures with low shrinkage

- Formulated with a low solvent concentration

Applications

- Bonding of :

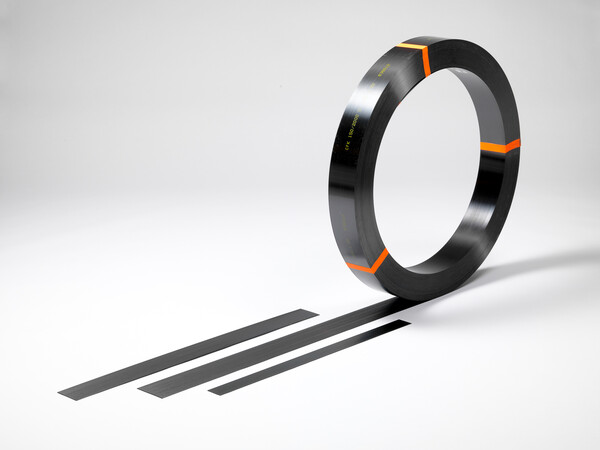

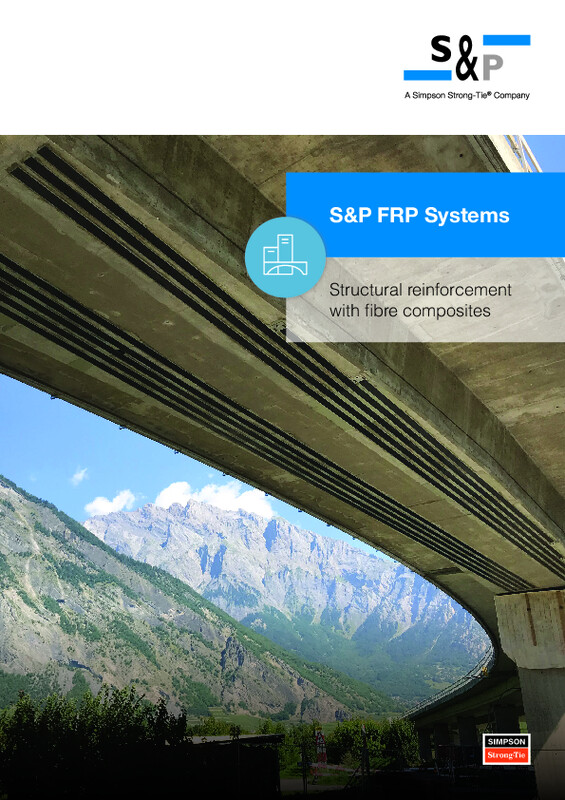

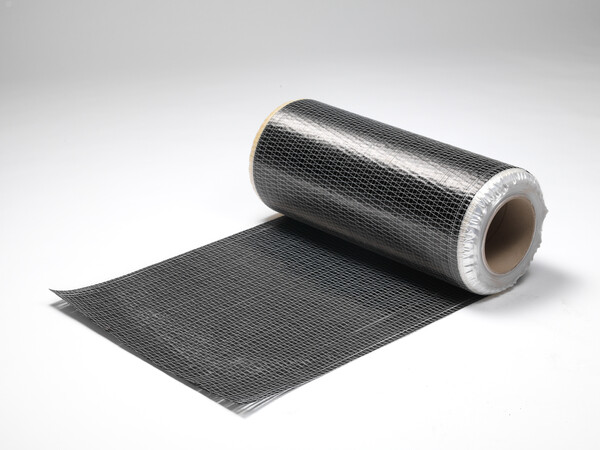

- S&P C-Laminate on concrete and Steel

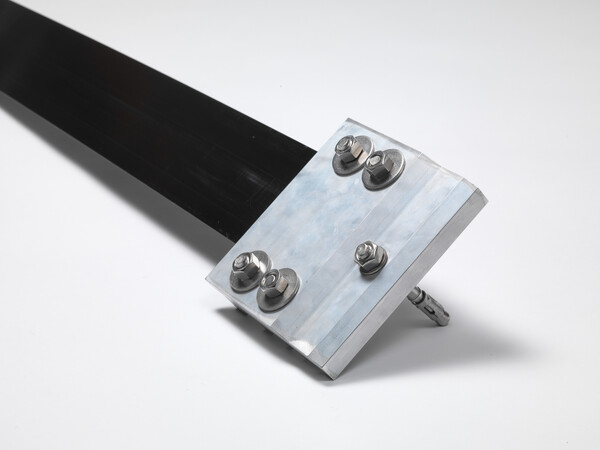

- Steel strips and plates on concrete