S&P Product - Trail

JOSN

Product Information

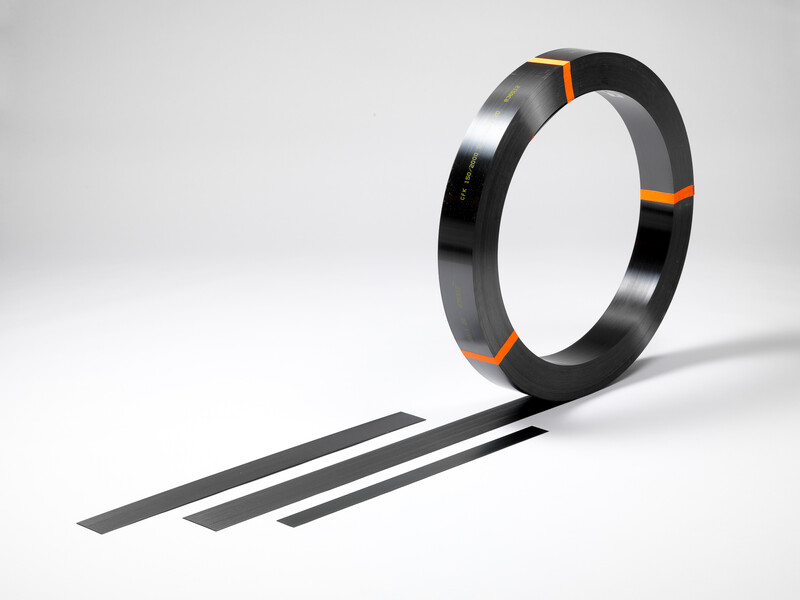

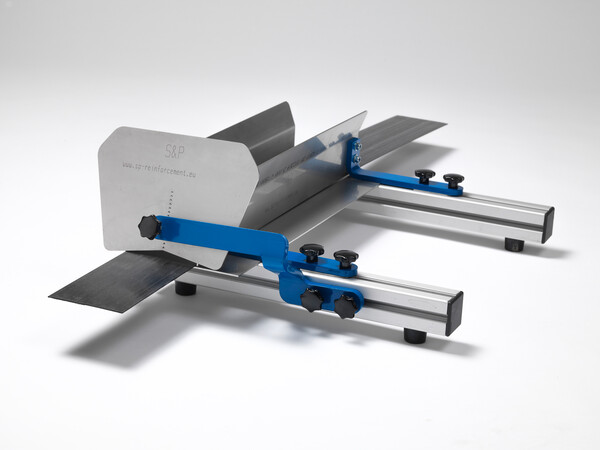

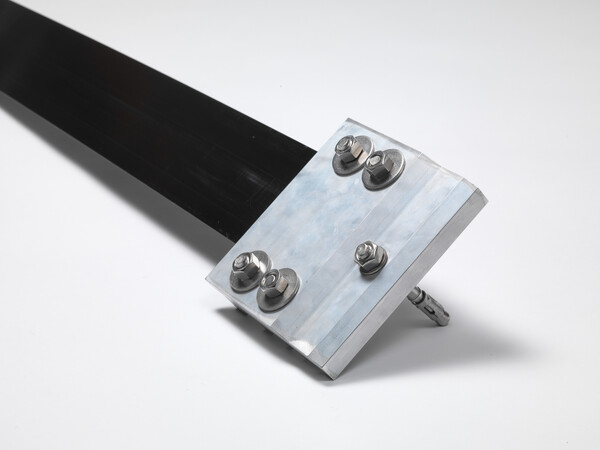

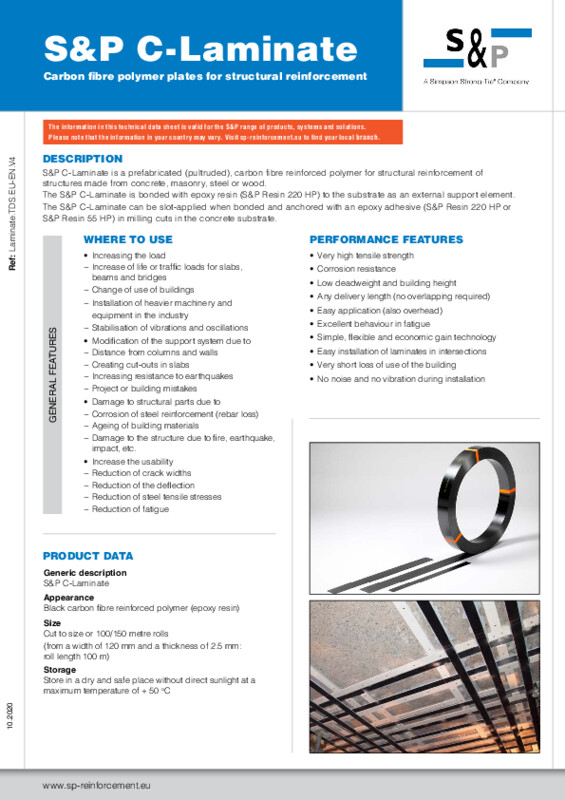

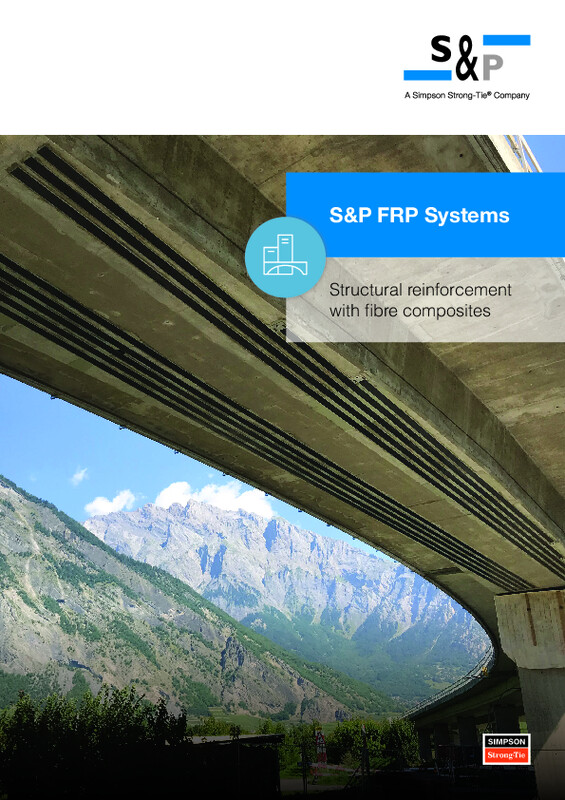

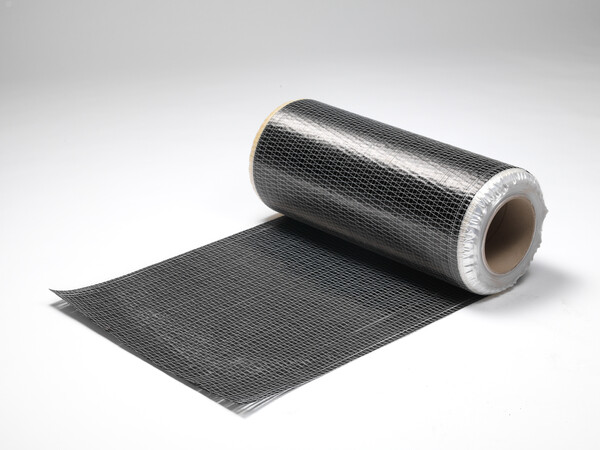

S&P C-Laminate is a prefabricated (pultruded), carbon fibre reinforced polymer for structural reinforcement of structures made from concrete, masonry, steel or wood. The S&P C-Laminate is bonded with epoxy resin (S&P Resin 220 HP) to the substrate as an external support element. The S&P C-Laminate can be slot-applied when bonded and anchored with an epoxy adhesive (S&P Resin 220 HP or S&P Resin 55 HP) in milling cuts in the concrete substrate.

Features and Applications

Feature

- Very high tensile strength

- Corrosion resistance

- Low deadweight and building height

- Any delivery length (no overlapping required)

- Easy application (also overhead)

- Excellent behaviour in fatigue

- Simple, flexible and economic gain technology

- Easy installation of laminates in intersections

- Very short loss of use of the building

- No noise and no vibration during installation

Applications

- Increasing the load

- Increase of life or traffic loads for slabs, beams

and bridges

- Change of use of buildings

- Installation of heavier machinery and equipment in

the industry

- Stabilisation of vibrations and oscillations

- Modification of the support system due to

- Distance from columns and walls

- Creating cut-outs in slabs

- Increasing resistance to earthquakes

- Project or building mistakes

- Damage to structural parts due to

- Corrosion of steel reinforcement (rebar loss)

- Ageing of building materials

- Damage to the structure due to fire, earthquake,

impact, etc.

- Increase the usability

- Reduction of crack widths

- Reduction of the deflection

- Reduction of steel tensile stresses

- Reduction of fatigue