Holledau bridge

The listed Holledau viaduct is a busy bridge on the A9 motorway in the south of Bavaria that was built in 1937. The structure was blown up by the military in 1945 and the reconstruction was completed in 1949. Between 1978 and 1979, the South Bavarian Motorway Authority had the bridges rebuilt as part of the widening of the motorway to three lanes in each direction.

On this page

- Topic

- Thin asphalt layer in hot installation with carbon fibre grid reinforcement

- Object

- Holledau bridge, A9 Motorway

- City

- Geisenhausen

- State

- Bavaria

- Country

- Germany

- Date

System

Project Description

Situation

In the past, repeated cracking down to the waterproofing layers of the bridge led to frequent and cost-intensive repairs. A particularly critical point was the additionally installed frost sensors which intensified the cracking in the asphalt layers above - and made a long-term solution even more urgent. The repetitive damage had led to long closure periods, high repair costs and limited availability of the infrastructure.

These challenges were reason enough for our sales partner Nadler Strassentechnik GmbH and the South Bavarian Motorway Authority to develop and implement a sustainable special solution for the bridge structure.

The construction project was conducted as part of the upgrading of the motorway shoulder for temporary traffic use between Allershausen and the Holledau intersection. The targeted use of modern construction materials and optimised construction methods was designed to, not only significantly improve the durability of the carriageway, but also considerably reduce the maintenance costs - a benefit for operators and road users alike.

Solution

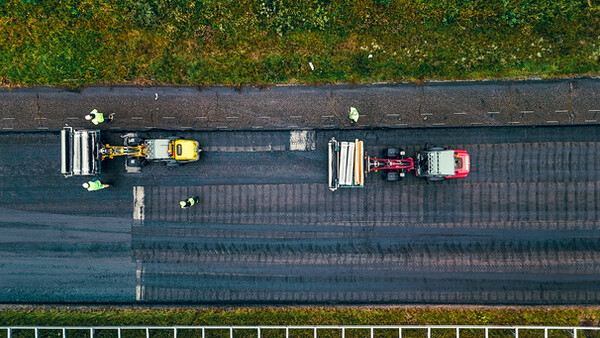

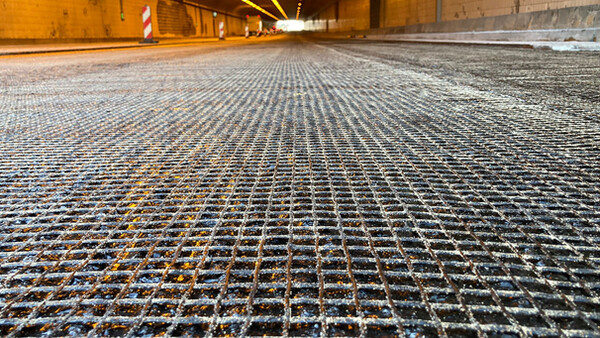

In the past, asphalt reinforcements were successfully used under thin layers (hot) in Bavaria (City of Munich) to prevent reflection cracks and rutting. In this case, S&P Carbophalt® G asphalt reinforcement grid was installed under 2 cm of DSH-V 5. The unique properties of the product make it possible to construct a thin superstructure with 2 cm of asphalt and to achieve outstanding effectiveness.

Project tracking

The current condition shows the result of the successfully applied special solution. To date, hardly any damage or deformation is recognisable and the S&P Carbophalt® G product continues to support the asphalt package by distributing the loads evenly and preventing cracking. According to the responsible road construction authority, the expected service life without reinforcement was around 2 years. With S&P Carbophalt® G, it could be extended by a factor of at least 4. A true example of how sustainable construction methods and innovative materials go hand in hand. On top of that, the great success of renovations such as this one led to further research in the form of a laboratory test.

CO2 Savings

The service life of the asphalt wearing course without asphalt reinforcement was estimated by the road construction authority to be around 2 years. Using this data, we conducted a comparative analysis based on Global Warming Potential (GWP) figures from national databases like OEKOBAUDAT. By implementing S&P's solution, CO₂-equivalent emissions from material usage alone were reduced by around 60 % over the observed 9-year period. This estimate considers only the materials; actual CO₂ savings would be even greater when including other factors such as milling, transportation, and general jobsite operations tied to repeated repairs.

Material

S&P Carbophalt® G 8000 m²