S&P FRP Systems

Structural reinforcement with fibre composites

System Description

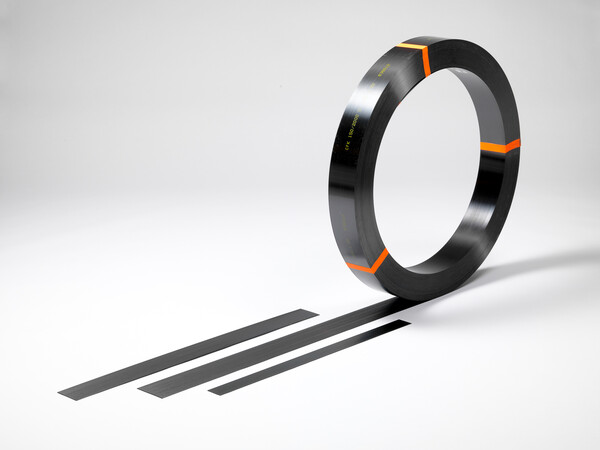

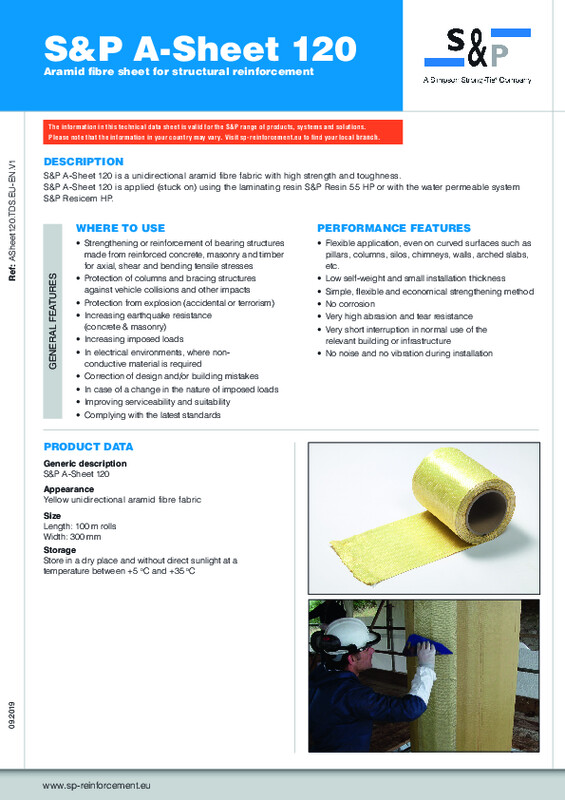

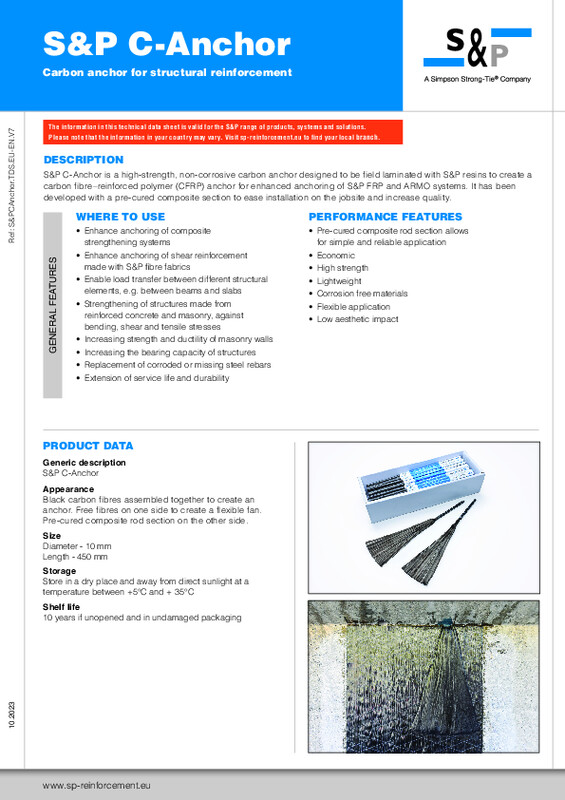

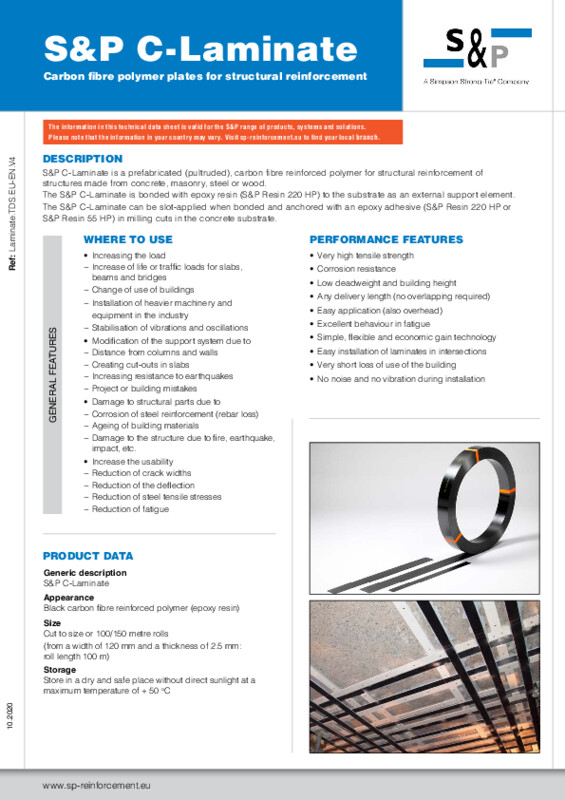

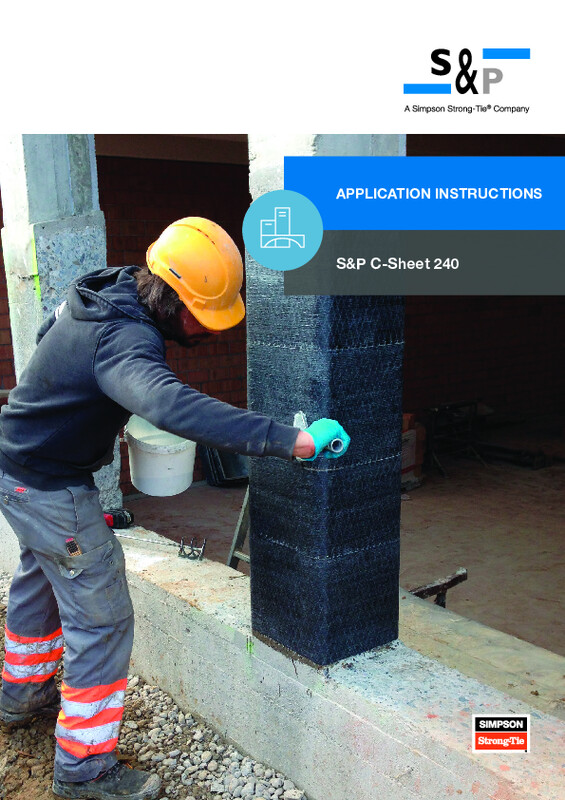

S&P FRP systems are made from carbon, aramid and glass fibres, which are installed using tested and certified epoxy adhesives and saturants

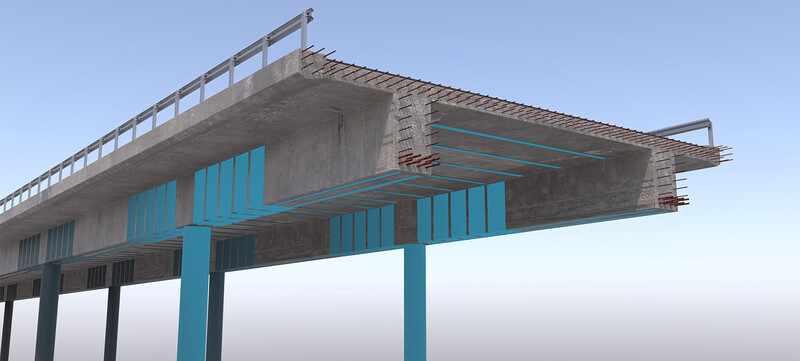

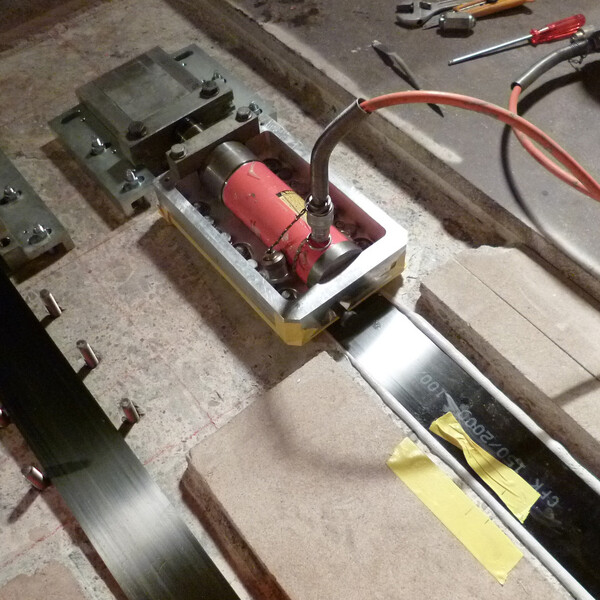

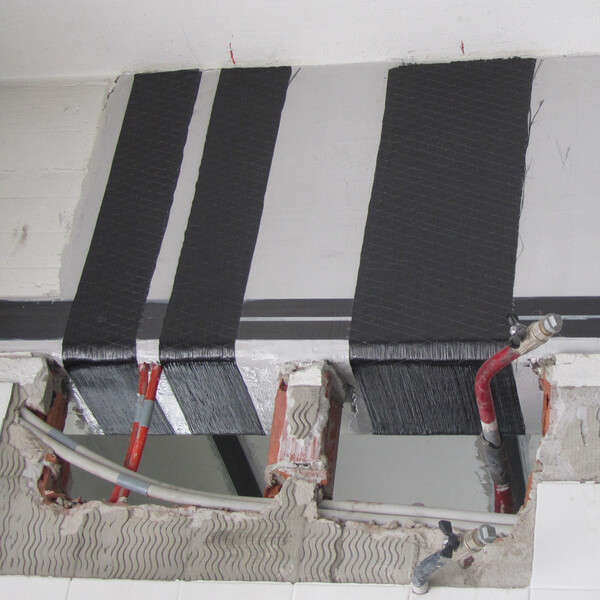

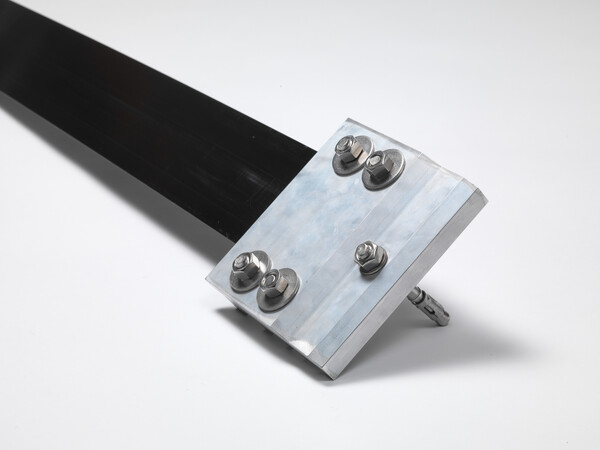

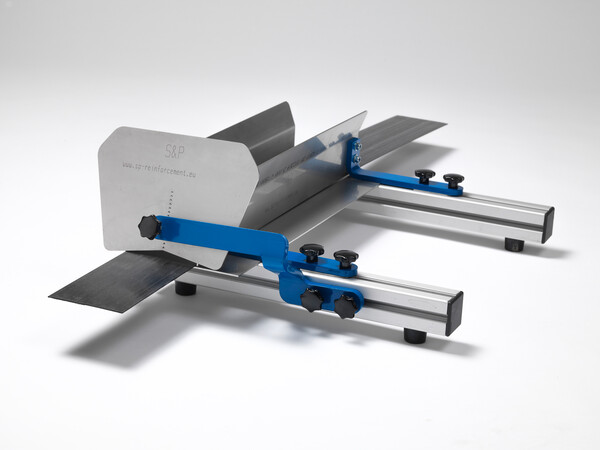

In civil and structural engineering, FRP systems are used for static reinforcement of structures during conversions, system adaptations or building upgrades. Depending on the structure material (concrete, masonry, steel, wood) or static requirement (bending moment, shear force, normal force, seismic load), either S&P C-Laminates or S&P Sheets can be installed. In cases where it is required to combat larger deflection or vibrations, pre-stressed S&P C-Laminates are often the preferred option. The high strength, lightweight and corrosion resistant reinforcement products and systems can be used in many applications. With the help of the S&P Adhesive-forming unit and the S&P Wet-lay-up machine for the pre-impregnation of S&P sheets, the application of the reinforcement on the construction site can be economically and efficiently improved. The S&P Software applications FRP Lamella and FRP Colonna provide assistance for the required static calculations.

On this page

Features and Benefits

Features

- Surface applied, slot applied and pre-stressed laminates (S&P C-Laminates)

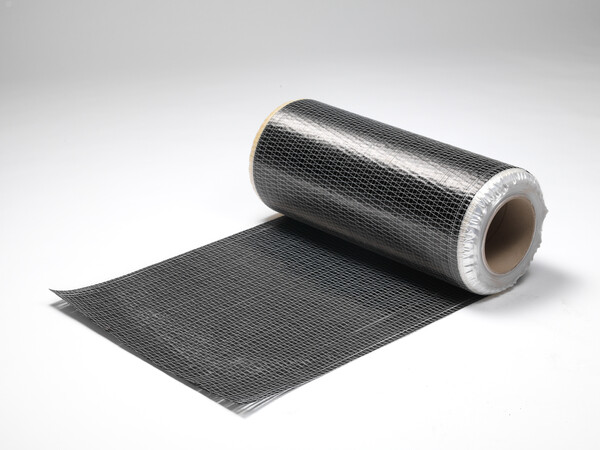

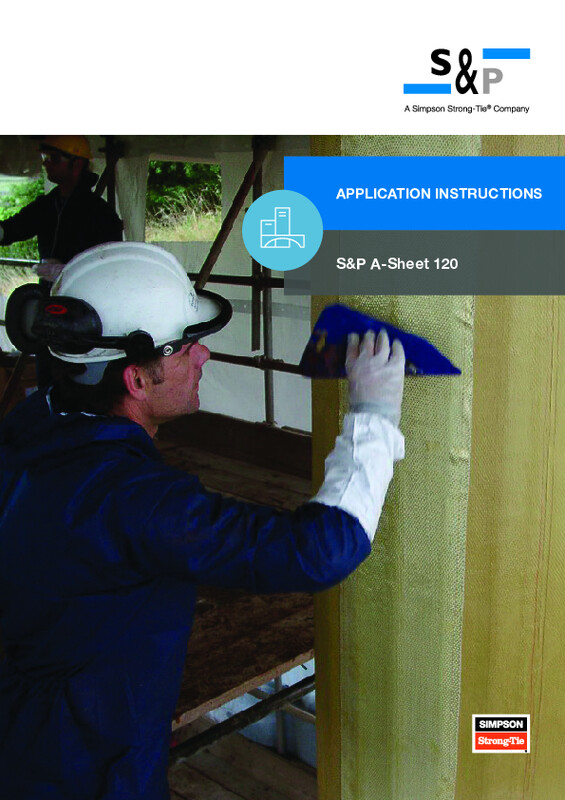

- Carbon, glass and aramid fibre sheets (S&P Sheets)

- Epoxy adhesives and laminating resins

- Devices and processing aids

- Software

- Engineering services

Benefits

- Very high tensile strength and excellent behaviour in fatigue

- Low deadweight and building height

- Fast, simple installation, therefore resulting in low downtimes

- Flexible and economic technology

- Durable, corrosion resistant materials