Sustainability

The durability, millability and recyclability of S&P grids result in sustainable solutions

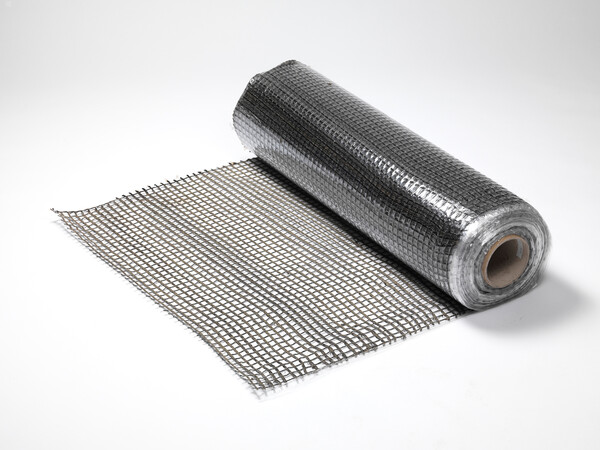

S&P Asphalt reinforcement grids are widely recognised as being a long term sustainable option when it comes to reinforcing roads and pavements.

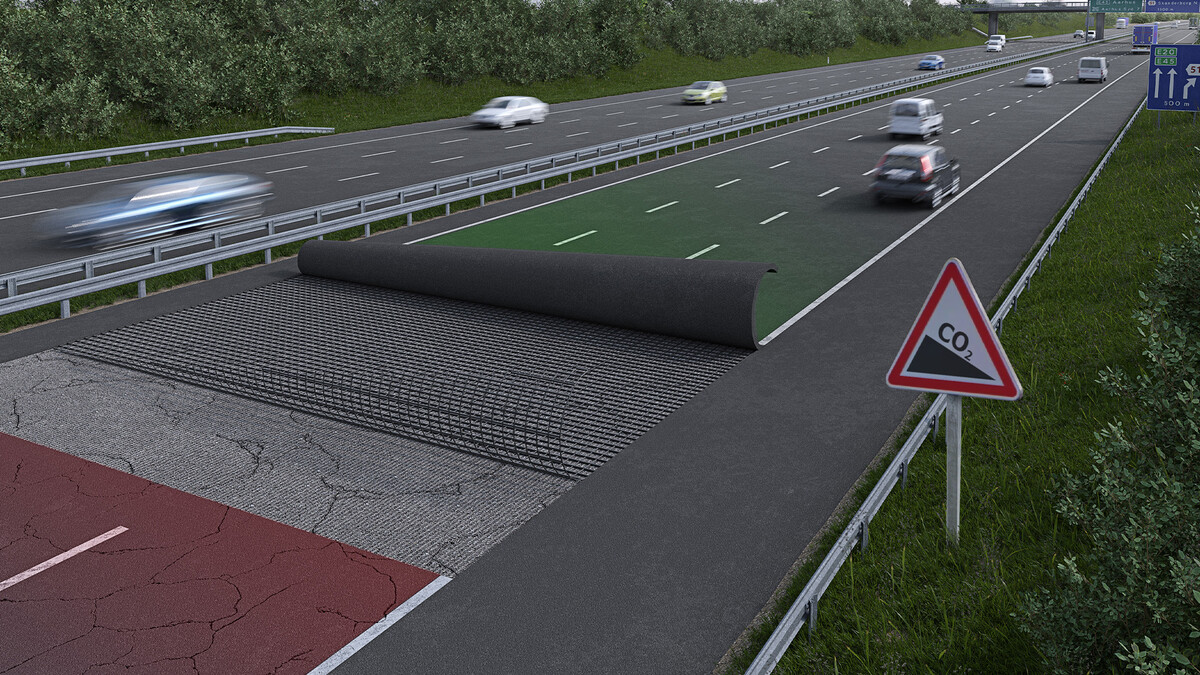

When considering traditional repair methods, frequent repair cycles of recurring problems with roads, leads to an increase in CO2 emissions through a variety of factors such as the amount of asphalt needed for relaying and re-surfacing roads, as well as the frequent required use of the machinery involved during the repair.

Imagine if these repair cycles could be less frequent and the durability of the road could be increased? This is where S&P come in. S&P asphalt reinforcement grids are a durable solution. By installing S&P asphalt reinforcement grids on your projects, you are guaranteeing that the road will last longer – therefore working towards a more sustainable infrastructure, where the length of repair cycles are significantly extended.

Not only that, should there indeed be a need in the future to repair or re-structure the road network, S&P asphalt reinforcement grids are millable and recyclable. This offers peace of mind, knowing that when the time comes in the distant future to mill the road, the presence of the S&P asphalt reinforcement grid between road layers will not cause a problem for machinery and the milled material is completely re-usable.

Related Content

CO2 savings on previous projects

The use of Global Warming Potential (GWP) figures enables the calculation of CO2 savings from past projects

Before installing our asphalt reinforcement grids, we sometimes have information about the alternative solutions proposed or the historical repair cycle length. With this data, we can perform comparison calculations using Global Warming Potential (GWP) figures for asphalt mixes from various national databases, as well as CO2 emission data from our independently verified Environmental Product Declarations (EPDs). This capability allows us to quantify the actual CO2 savings achieved by installing S&P asphalt reinforcement grids compared to alternative solutions, which often lead to significantly higher material consumption and emissions.

Millable and Recyclable

Asphalt reinforcements made of glass and carbon fibres from S&P can be milled and recycled without problems. This has been proven by various practical tests across Europe.

The use of S&P asphalt grids with low temperature asphalt

The market is witnessing a notable shift towards the adoption of low temperature asphalt, primarily driven by sustainability considerations. In this evolving landscape, our asphalt reinforcement grids have emerged as a compelling solution, demonstrating remarkable effectiveness when utilised alongside low-temperature asphalt applications. Through meticulous research and testing, we have established the compatibility and synergy between our reinforcement grids and these eco-conscious asphalt mixes. This combination not only addresses the pressing sustainability concerns but also delivers enhanced performance and durability, meeting the evolving needs of modern infrastructure projects. As pioneers in this domain, we remain committed to driving sustainable practices and offering innovative solutions that contribute to a greener, more resilient future.

Contact us to find out more