Low temperature asphalt and S&P reinforcement

Related Content

In order to save energy in road construction and thus reduce CO2 emissions, the use of low temperature asphalt is a major topic across a wide variety of countries and regions. In addition, there are ever stricter regulations regarding other emissions such as vapours and aerosols, which can also be reduced with low temperature asphalt. In the course of the changeover to low temperature asphalt, not only the asphalt must be tested for its functionality and workability, but also other construction materials such as asphalt reinforcement grids which are used in road construction projects.

S&P therefore commissioned the German engineering company PTM Dortmund GmbH to test what influence this temperature reduction has on the layer bond when S&P Glasphalt® G is used as a reinforcement interlayer.

Test Setup

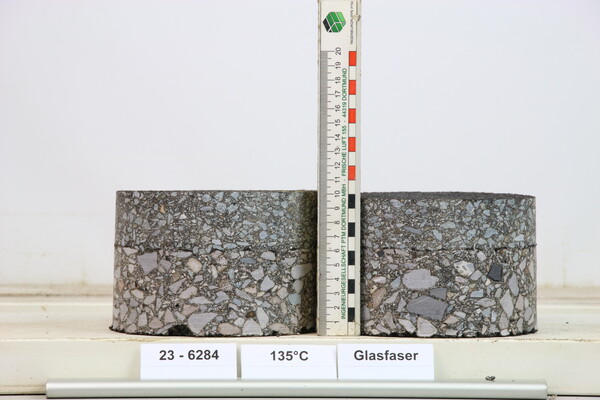

In the laboratory, asphalt sample slabs with mix temperatures of 155 °C as a reference, 135 °C and 110 °C were produced using a rolling sector compactor. The asphalt test slabs consisted of a 6 cm thick base layer made from AC 16 BS with PmB 25/55-55 A as binder and a top layer made from AC 8 DS with PmB 25/45 VL as a binder. To create the layer bond, the two-layer test specimen was sprayed with 250 g/m² C60 BP4-S bitumen emulsion and the asphalt reinforcement grid S&P Glasphalt® G was installed on the broken emulsion. As a reference, a construction variant without asphalt reinforcement was also produced and tested in parallel at the same temperatures.

Subsequently, two cores with a diameter of 150 mm were taken from each of the asphalt sample slabs produced and shear tests were carried out in accordance with TP Asphalt-StB Part 80.

Results

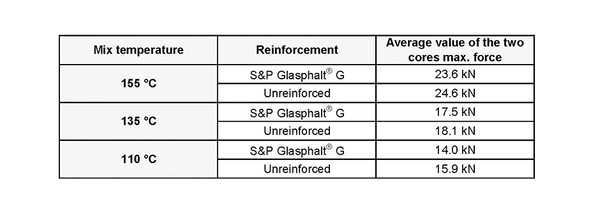

In principle, the test specimens with asphalt reinforcement S&P Glasphalt® G show a comparable level of layer bonding to the reference variant across the entire tested temperature spectrum. Furthermore, the reduction in temperature of the asphalt mix led to reduced force absorption or reduced layer bonding in all variants.

The values determined for the layer bond for all variants - despite optimum laboratory conditions - are generally at a low level. It can be assumed that significantly higher values can be achieved in construction practice with the appropriate use of pavers and rollers.

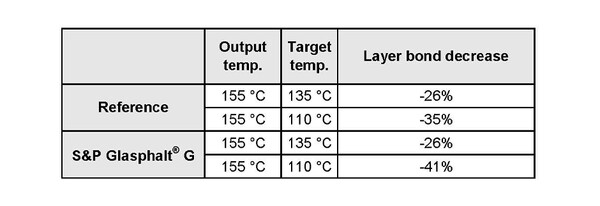

Working together to reduce emissions

The series of tests clearly revealed that the layer bond when using the asphalt reinforcement S&P Glasphalt® G is at a comparable level across all three tested overlay temperatures. In percentage terms, the reinforced compared to the unreinforced interfaces show an almost comparable decrease as a result of the temperature reduction. The use of S&P Glasphalt® G is therefore possible without any problems when used in combination with low temperature asphalt.

The combination of low temperature asphalt with asphalt reinforcement from S&P thus proves to be effective: emissions during paving can be reduced and at the same time the reinforcement reduces the consumption of resources by extending the service life of the road.