CO2 savings on previous projects

The use of Global Warming Potential (GWP) figures enables the calculation of CO2 savings from past projects

Before installing our asphalt reinforcement grids, we sometimes have information about the alternative solutions proposed or the historical repair cycle length. With this data, we can perform comparison calculations using Global Warming Potential (GWP) figures for asphalt mixes from various national databases, as well as CO2 emission data from our independently verified Environmental Product Declarations (EPDs). This capability allows us to quantify the actual CO2 savings achieved by installing S&P asphalt reinforcement grids compared to alternative solutions, which often lead to significantly higher material consumption and emissions.

Related Content

Over 70 % CO2 Emission Savings in Würzburg on project tracked over 18 years

Before the implementation of S&P asphalt reinforcement grids, the wearing course on this road had a service life of just 5 to 7 years. Based on this data, we performed a comparative analysis using Global Warming Potential (GWP) values from the national OEKOBAUDAT database. With the introduction of the S&P reinforcement solution, CO₂-equivalent emissions from material use alone were reduced by over 70% across an 18-year period. This calculation accounts solely for materials; total emissions savings would be even higher when factoring in additional aspects such as milling, transportation, and general site operations associated with repeated maintenance cycles.

More than 60 % CO2 Emission Savings on key Bavarian bridge with thin asphalt superstucture

The service life of the asphalt wearing course without asphalt reinforcement was estimated by the road construction authority to be around 2 years. Using this data, we conducted a comparative analysis based on Global Warming Potential (GWP) figures from national databases like OEKOBAUDAT. By implementing S&P's solution, CO₂-equivalent emissions from material usage alone were reduced by around 60 % over the observed 9-year period. This estimate considers only the materials; actual CO₂ savings would be even greater when including other factors such as milling, transportation, and general jobsite operations tied to repeated repairs.

Approximately 60 % CO2 Emission Savings in Warsaw

With the knowledge that the road required re-paving every three years prior to the intervention with S&P asphalt reinforcement grids, we were able to use this information to perform a calculation comparison utilising Global Warming Potential figures from various national databases. By implementing the solution provided by S&P, CO₂-equivalent emissions were reduced by approximately 60% in material usage alone on this project over the observed 10-year period. This calculation focuses solely on materials; the actual CO₂ savings would be significantly higher when factoring in additional activities such as milling, transport and general jobsite operations associated with repeated repair cycles.

80 % CO2 Emission Savings on district roads in Brandenburg

Based on figures from the Swedish National Road Administration (Trafikverket), the use of S&P asphalt reinforcements in this project resulted in a saving of approximately 1,700 t CO2eqv - or 79.68 % - compared to replacing the entire bonded superstructure.

This figure alone underlines the opportunities that the use of modern asphalt reinforcement systems from S&P offer for a sustainable transformation of road construction.

Around 44 % CO2 Emission Savings on Tunnel project in Munich

Until S&P asphalt reinforcement grids were installed, this section of road required repaving on a yearly basis. By utilising this data it has been possible to make a CO2-saving calculation based on Global Warming Potential (GWP) figures from the OEKOBAUDAT national database. During the observed 3 year period the solution implemented using S&P asphalt reinforcement grids has led to a reduction in CO₂-equivalent emissions - from material usage alone - of around 44%. As this calculation considers only the materials used, actual CO₂ savings would be even greater when including other factors such as milling, transportation and general jobsite operations tied to repeated repairs. Should the road continue to remain damage free and in no need of rehabilitation, this CO₂-equivalent emissions savings will continue to increase yearly, based on the previous yearly rehabilitation cycle of the road section.

At least 50 % CO2 Emission Savings on heavily trafficked highway in Brazil

On this project, a direct comparison between lanes 3 and 4 enabled a calculation using Global Warming Potential figures from various national databases to demonstrate the impact of S&P’s solution on CO₂ emissions reduction. Lane 4, reinforced with S&P materials, proved significantly more sustainable than the unreinforced lane 3. Over the observed 45-month period, CO₂-equivalent emission reductions were at least 50 % based on material usage alone on this project. These figures focus solely on material savings; actual CO₂ reductions would be considerably higher when including additional factors such as milling, transport, and other jobsite operations required for repeated repair cycles.

CO2 Emission Savings of 40 % on West Pomeranian State Road

Knowing that the previously proposed solution would have required a new 27 cm superstructure enabled a calculation using Global Warming Potential figures from various national databases to evaluate the impact of S&P’s solution on CO₂ emissions reduction. The results show that the double-layered S&P asphalt reinforcement grid solution achieved approximately 40% CO₂-equivalent emission reductions in material usage alone for this project. These figures account only for material savings; the actual CO₂ reductions would be significantly higher when considering additional factors, such as the increased milling, transport and other jobsite operations associated with the much thicker initial superstructure proposal.

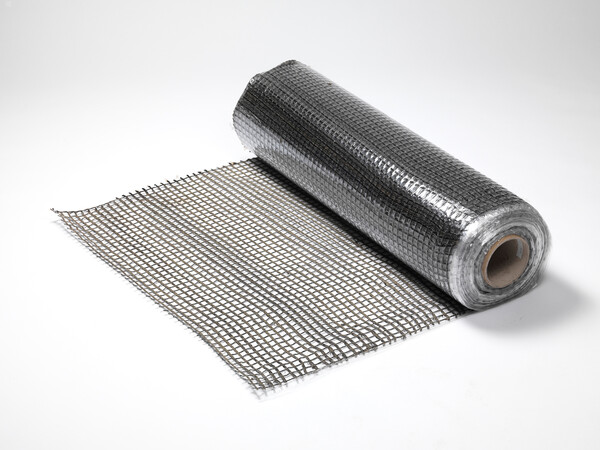

Featured Products

Contact us to find out more