S&P Asphalt reinforcement

Fibre reinforcement grids for asphalt surfaces

Concept and Components

The reinforcement of masonry against seismic stress is playing an increasingly important role in the strengthening of buildings. Masonry is cost-effective and is therefore a widely used construction method worldwide. Thanks to its good structural-physical properties, it will continue to be used in the future. However, the strength of masonry is subject to large fluctuations due to different brick and mortar qualities.

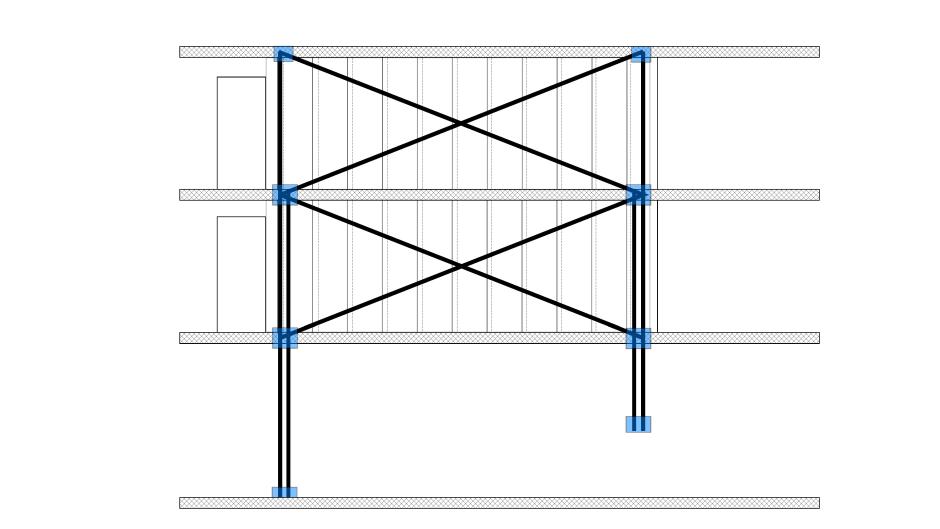

The S&P concept for seismic reinforcement includes high quality levelling mortar, glass or carbon fibre mesh, as well as diagonally and vertically arranged bonded reinforcements. Specially manufactured steel parts anchor the louvres in the adjacent concrete components.

Schematic representation of seismic masonry reinforcement over several storeys. Image: S&P

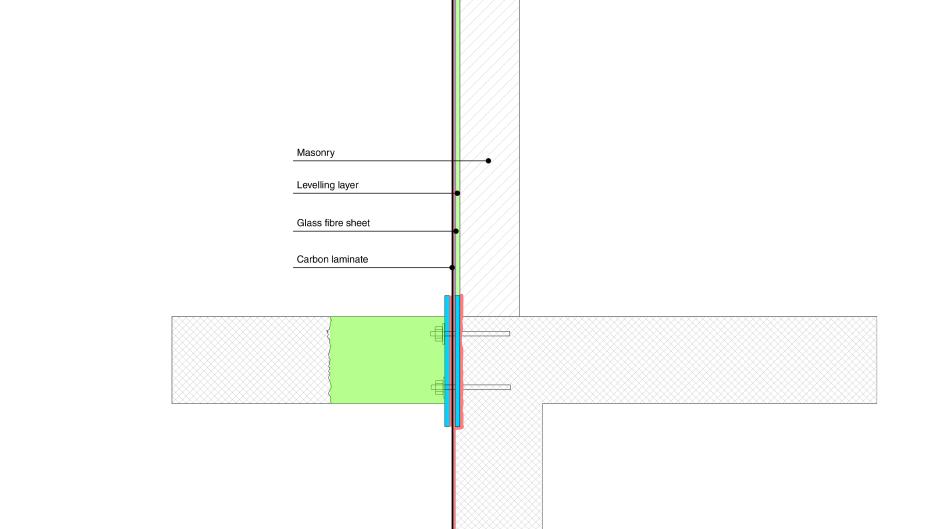

Before applying the reinforcement, the base render and other layers must be removed down to the masonry. The levelling mortar S&P Tecnogrout-K can now be applied to the cleaned masonry surface. After drying, the surface must be sanded as with other adhesive reinforcements and the specifications regarding evenness and substrate moisture content must be adhered to.

The application of the S&P G-Sheet serves to increase the ductility of the masonry wall and to distribute the adhesive tensile stresses of the laminates over a larger bonding area in order to prevent premature delamination of the laminates.

By installing steel anchoring elements, the horizontal loads from the slab levels are absorbed and the forces are transferred to the carbon fibre laminates. The use of sandwich elements with corresponding anchoring in the slab level in the form of headed shear studs, shear bolt dowels or similar has proven its worth. The steel components are essential for the overall system and therefore require customised and well-founded planning by our engineering department.

S&P C-Laminates are usually applied in a vertical and diagonal direction to absorb the forces. Only tensile forces can be absorbed, compressive forces must be absorbed by the masonry, in many cases this is decisive for the maximum achievable reinforcement.

Reliable anchoring of the louvres is extremely important for seismic reinforcements, as otherwise they can delaminate in the event of an incident and the reinforcement would lose its effect. Our system structure prevents the laminates from detaching themselves from the substrate in the event of an earthquake. Without bonding, it would require full elongation over its entire length before its resistance is realised. This would mean changes in length of several centimetres. As a rule, masonry walls cannot absorb such displacements.

The structure of a seismic reinforcement of masonry in detail. Image: S&P

The planning and assessment of seismic reinforcement projects is always the responsibility of the project engineer. With our decades of experience from various projects worldwide, we support you with your masonry reinforcement and contribute our expertise in the following areas:

Simply ask us, and our engineers and application technicians will be happy to support you!